Digiflow FlowX3 Flow Meters

Digiflow Flow Meters and Instrumentation

The Digiflow® FlowX3 line includes a complete range of paddle wheel flow sensors, instruments and sensor installation fittings. Also included are insertion type electromagnetic flow transmitters. FlowX3 products provide high quality and state-of-the-art technology. All products are manufactured under ISO 9001:2000 and conform to the highest CE standards.

Features & Benefits

- High Accuracy

- Excellent Low Flow Measurement

- Large Flow Velocity Range

- Easily Installed into all Types of Piping

Sensor installation fittings are available in a large selection of types, materials and pipe sizes

Technical Documents

Commonly used in these markets

Process Industrial

Chemical, Storage & Transport

Aquatic Life Support

Pools, Water Parks

Utility Water

Sensors

FlowX3 paddle wheel flow meters are of corrosion resistant solid plastic construction. They are recommended for services with up to 10% solids*. Bearings and sensor body near the rotor are designed to be self-cleaning and small magnets in the rotor blade lessen the chance of fouling due to accumulation of magnetic particles in the process. NEMA 6, 6P (IP68) models are available for outdoor or submersible installations.

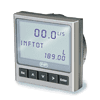

Instruments

FlowX3 instruments were first introduced in 2003. The line of instruments has since expanded. A large offering of control outputs includes 4 to 20 mA, open collector (pulse) and relays. All units have LCD displays and LEDs for indication of output status.

Only with Digiflow® FlowX3 can the same instrument be mounted in 3 different ways: directly to the flow sensor, remotely in a panel or on a wall.

M9.00 M9.00 |

M9.02 M9.02 |

M9.03 M9.03 |

M9.10 M9.10 |

M9.20 M9.20 |

M9.50 M9.50 |

|

|---|---|---|---|---|---|---|

| Instrument | Flow Monitors / Transmitters | Dual Input Analog Monitor / Transmitter | Dual Input Flow Monitor / Transmitter | Battery Powered Flow Monitor | Batch Controller | |

| Configuration Chart | ||||||

| Power Supply | 12-24 VDC | 12-24 VDC | 12-24 VDC | 12-24 VDC | 3.6V Lithium Thionychloride battery size C | 12-24 VDC |

| Outputs | ||||||

| Solid State Relay (SSR) | 1 | 2 | 2 | 2 | – | 2 |

| Open Collector Relay (OC) | – | – | – | – | – | – |

| Mechanical Relay (SPDT) | – | 1 | 2 | 2 | – | 2 |

| Analog Output Signal | 1 X 4-20 mA | 1 X 4-20 mA | 2 X 4-20 mA | 2 X 4-20 mA | Visual Display Only | – |

| Wiring | 2-wire | 3/4-wire | 3/4-wire | 2-wire | 3/4-wire | |

| Compatible Sensors | ||||||

| Coil – Paddle Wheel | – | – | – | – |  |

– |

| Hall – Paddle Wheel |  |

|

|

|

– |  |

| Hall – ULF | – |  |

|

|

– |  |

| Reed – ULF |  |

– |  |

– |  |

– |

| Electromagnetic | – |  |

|

|

– |  |

| Analog 4-20mA Sensos | – | – | – |  |

– | – |

| M9.00 | M9.02 | M9.03 | M9.10 | M9.20 | M9.50 | |

Installation Fittings

For all Digiflow Sensors: Tees, Bolt-on Saddles, Metal Strap-On Saddles, Weld-On Adaptors, 316 SS Threaded Tees, Hot-Tap Fittings and Saddles, Plugs.

Valve Specification Guide

Engineering specifications are crucial as they provide precision, clarity, quality assurance and compliance in your projects. Download to save you time and assure accuracy in your specifications.

Chemical Resistance Guide

Corrosion resistance is an important factor in selecting the right material of construction for valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.

Materials of Construction

Understanding materials of construction is essential to the accurate selection of valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.